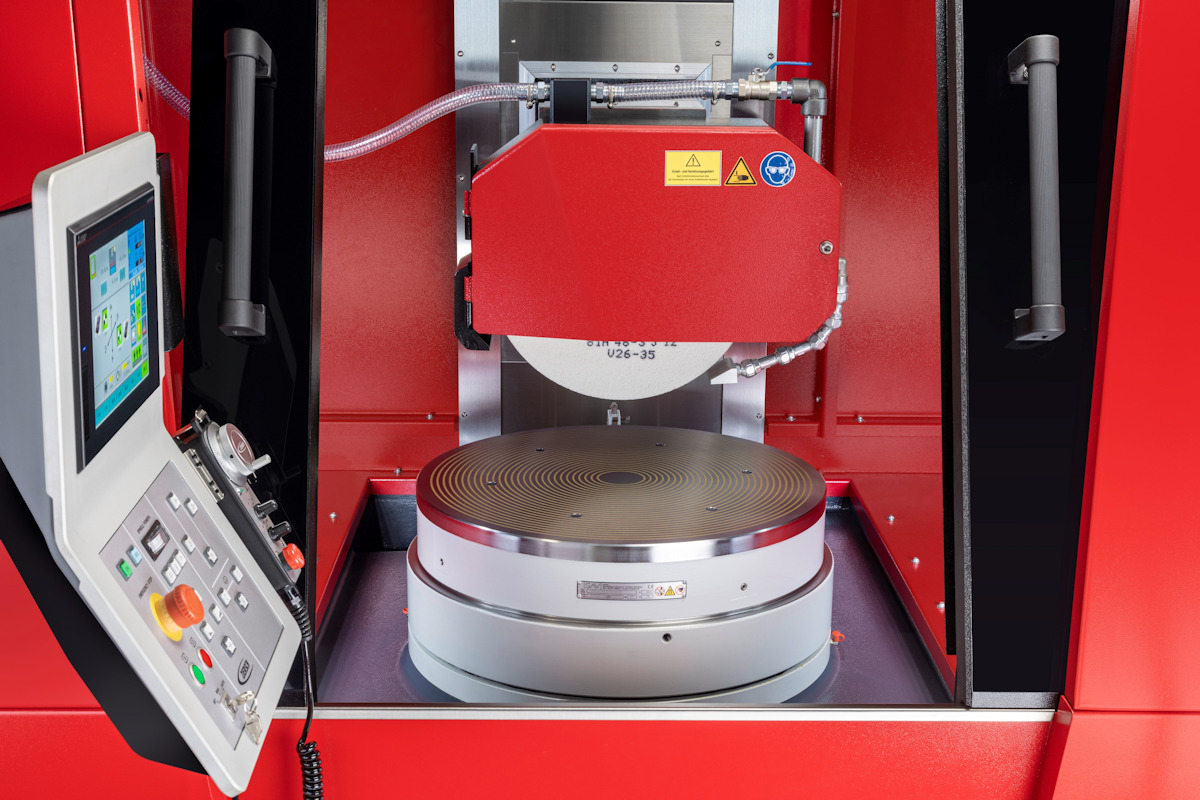

Rotary table grinding machines Z-SERIES

Control

- User-friendly Z-Control with high comfort

- Manual grinding function with open door

- Fully automatic grinding cycle with dressing cycles

- Grinding cycles: surface grinding and plunge grinding

- Grinding modes: roughing, finishing and spark out

- Dressing cycles divided into roughing and finishing

- Automatic vertical infeed with compensation of the dressing amount

- Warm-up and night shutdown programs

- Easy and intuitive operation through a large, user-friendly touchscreen

- Electronic handwheel, usable in the Y- and Z-axis, switchable in two stages to 0.001 and 0.01 mm

- Rigid cast iron machine components

- High machine weight for maximum rigidity

- Full enclosure of the machine with sliding door and front-end mounted service doors; effective splash protection with excellent accessibility

- Preloaded precision linear guideways in the Y- and Z-axis (Bosch Rexroth) for highest accuracy

- Hydrostatic bearing or

- Rolling bearing, grease-lubricated for life

- Hydrostatic: Automatic central lubrication in all axes

- Rolling bearing: Automatic central lubrication in the Y- and Z-axis (grease)

- Electromechanical drive of the Y- and Z-axis and rotary table

- Precise positioning using a direct measuring system on the Y-axis (Heidenhain) and a rotary encoder on the Z-axis

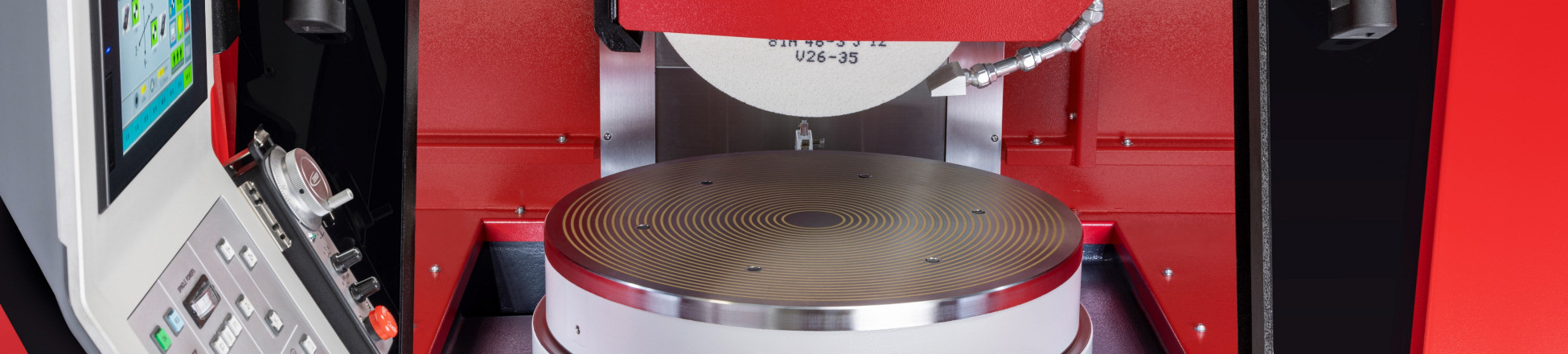

- Grinding spindle separated from motor via coupling, eliminating heat transfer

- Continuously adjustable grinding spindle motor with constant cutting speed up to 35 m/s (optionally up to 50 m/s) over the entire range of use of the grinding wheel (vconstant)

- Long service life due to a grinding spindle supported by 6 rolling bearings, grease-lubricated for life

- Heat-free electro-permanent magnetic chuck

- Integrated pole-reversal control unit with 16 different clamping forces

- Maintenance-free belt filter system with integrated channel flushing incl. cleaning gun with hose and magnetic separator for pre-filtration